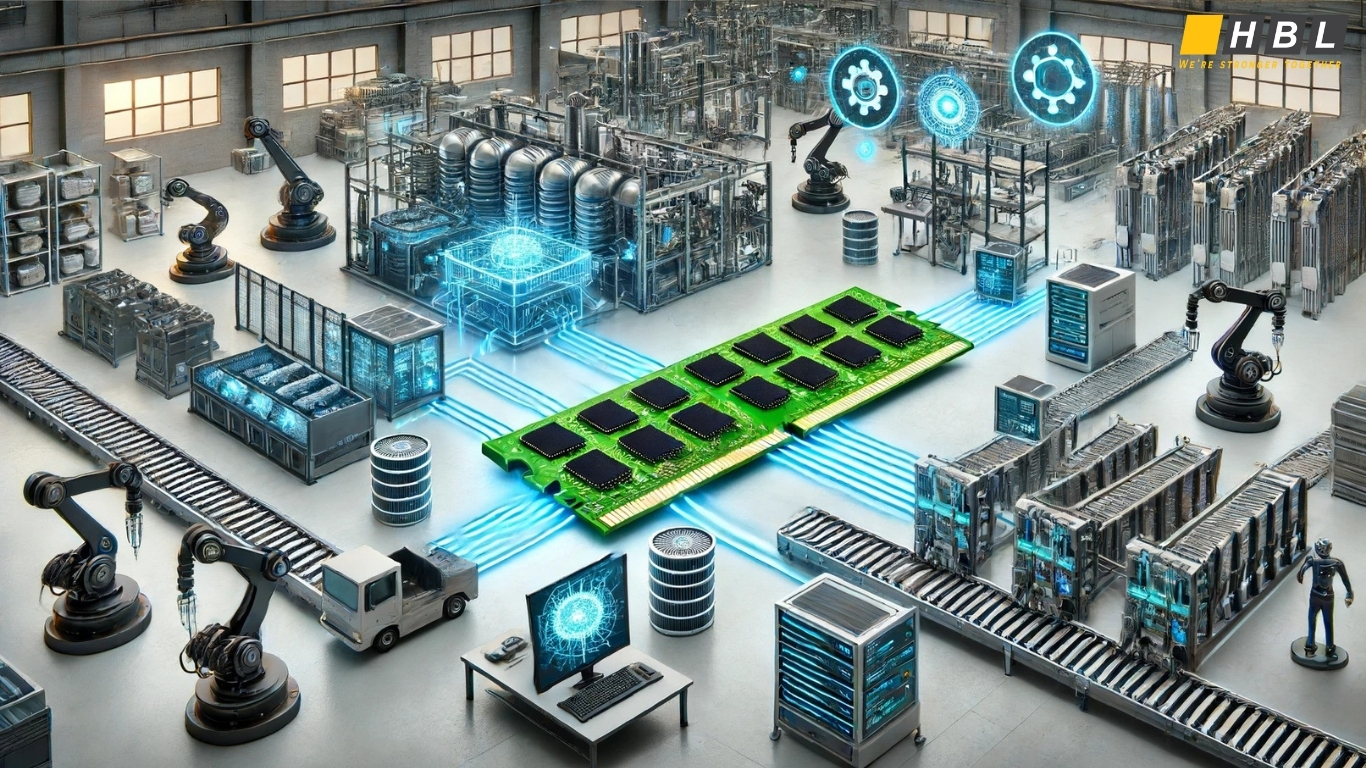

AI in industrial automation is revolutionizing manufacturing, driving efficiency, and reshaping smart factories for a data-driven future. As manufacturers increasingly adopt AI to boost productivity, AI in industrial automation has become essential for staying competitive.

This article explores how AI in industrial automation enhances processes, delivers measurable benefits, and addresses global challenges like cost optimization and scalability. From predictive maintenance to intelligent robotics, discover how AI in the automation industry transforms operations, with insights into HBLAB’s AI-driven industrial solutions.

What is AI in Industrial Automation?

AI in industrial automation refers to using artificial intelligence to enhance manufacturing processes, making factories smarter, safer, and more efficient. Unlike traditional automation, which relies on fixed rules, AI in automation industry leverages machine learning, computer vision, and IoT to enable real-time decision-making and adaptability.

For example, AI analyzes sensor data to predict equipment failures, ensuring seamless production.

This technology empowers industries to optimize workflows, reduce costs, and improve quality. Machine learning in industrial automation allows systems to learn from data, adapting to new conditions without manual intervention. As industries face talent shortages and rising costs, AI in industrial automation offers a scalable solution for global competitiveness.

How AI in Industrial Automation Works

AI in industrial automation transforms factory operations by integrating data, algorithms, and intelligent systems into a cohesive framework. This structured process enables AI in industrial automation to optimize manufacturing, enhance decision-making, and improve efficiency. By leveraging advanced technologies, AI in industrial automation ensures factories operate smarter and more adaptively. Below is a breakdown of how AI in industrial automation works:

Data Collection

AI in industrial automation begins with gathering real-time data from factory equipment. IoT sensors and smart devices capture metrics such as vibration, temperature, pressure, and production output.

For example, a temperature sensor on a motor provides continuous data to detect overheating risks. This step ensures AI in industrial automation has the raw information needed for intelligent analysis, forming the foundation of data-driven manufacturing.

Data Analysis

Machine learning in industrial automation, a core component of AI in industrial automation, processes collected data to uncover patterns and insights. Algorithms analyze historical and real-time data to predict equipment failures, optimize production schedules, or identify inefficiencies.

For instance, anomaly detection models flag irregular vibrations in a conveyor system, preventing breakdowns. This step empowers AI in industrial automation to turn raw data into actionable intelligence.

Explore HBLAB’s in-depth research on why Agentic AI matters

Decision-Making

AI in industrial automation uses edge computing or cloud platforms to make real-time decisions. Edge AI processes data locally for instant responses, like adjusting a robotic arm’s speed to match production demand. Cloud-based AI, meanwhile, handles complex computations, such as optimizing factory-wide energy use. These decisions, driven by AI in industrial automation, ensure precision and adaptability in dynamic environments.

Integration

AI in industrial automation seamlessly connects with existing systems like Supervisory Control and Data Acquisition (SCADA), Programmable Logic Controllers (PLCs), and Manufacturing Execution Systems (MES). Scalable AI solutions enhance these systems by adding intelligent control loops.

Feedback Loops

AI in industrial automation incorporates continuous feedback to refine performance. AI systems monitor outcomes of their decisions, such as maintenance schedules or production adjustments, and learn from results to improve accuracy.

For instance, if a predictive maintenance alert reduces downtime, the model updates its parameters to enhance future predictions. This iterative process strengthens AI in industrial automation, ensuring long-term reliability and efficiency.

By following this framework, AI in industrial automation ensures seamless adoption, aligns with business goals, and drives measurable improvements in manufacturing.

👉 Learn how HBLAB integrates AI in industrial automation for your factory!

Advantages of AI in Industrial Automation

AI in industrial automation offers transformative benefits, addressing global IT challenges like efficiency and cost optimization:

- Increased Efficiency: Smart factory automation streamlines processes, reducing cycle times. AI automates repetitive tasks, freeing workers for strategic roles.

- Cost Savings: Cost-effective AI automation cuts maintenance expenses through predictive maintenance with AI.

- Improved Quality: Top-rated tools for compliance-driven AI automation in regulated industries ensure precise defect detection.

- Enhanced Safety: AI-powered sensors monitor hazardous conditions, improving workplace safety.

- Sustainability: AI-driven industrial solutions optimize energy use, supporting eco-friendly manufacturing.

These advantages make AI in industrial automation a game-changer for manufacturers seeking scalability and competitiveness.

Challenges and Risks of AI in Industrial Automation

While AI in industrial automation drives innovation, it faces challenges:

- High Initial Costs: Implementing scalable AI solutions requires significant investment in infrastructure and training. Small manufacturers may struggle with upfront costs.

- Data Quality Issues: Machine learning in industrial automation relies on clean data. Incomplete or inconsistent data can lead to unreliable outcomes.

- Cybersecurity Risks: Increased connectivity raises concerns about data breaches. Robust security, like GDPR-compliant protocols, is essential.

- Workforce Resistance: Employees may fear job displacement. Training programs can ease transitions, ensuring collaboration with AI-driven industrial solutions.

- Integration with Legacy Systems: Retrofitting old equipment for AI compatibility can be complex, requiring expert integration.

Addressing these challenges with top-rated tools for compliance-driven AI automation in regulated industries ensures successful adoption.

AI in industrial automation is delivering measurable gains across uptime, quality, and compliance when paired with robust data pipelines, edge analytics, and governed MLOps in production environments.

In practice, “ai in industrial automation” strategies combine sensor-rich assets, digital twins, and machine learning to enable predictive maintenance, computer-vision quality inspection, and closed-loop optimization at line, cell, and plant levels.

Enterprises in regulated sectors are also adopting “ai in automation industry” approaches with validation and traceability baked into workflows to satisfy GMP and sector-specific controls while scaling automation benefits.

Agentic AI In-Depth Report 2026: The Most Comprehensive Business Blueprint

Case Study 1: Predictive Maintenance at Scale with Industrial AI

A widely referenced architecture for ai in industrial automation is AI-driven predictive maintenance that shifts maintenance from scheduled or reactive to condition-based and predictive using vibration, thermal, current, and acoustic signals streamed from machines.

The technical stack typically includes edge AI for local feature extraction, time-series pipelines to an IIoT platform, supervised models for failure-mode classification, and RUL (remaining useful life) estimation models tied to ERP/CMMS for automated work orders.

By moving analytics closer to the asset and synchronizing insights with enterprise systems, manufacturers reduce unplanned downtime while optimizing spare parts and labor, which is a core ROI driver of ai in automation industry deployments.

In documented results, industrial AI programs report measurable gains such as accelerated anomaly detection and earlier failure alerts, translating into lower MTTR and higher OEE when models are retrained on asset-specific data and integrated with maintenance scheduling.

ABB has described a practical mix of cloud-based longitudinal analytics and on-site monitoring to manage thousands of devices, reducing unexpected downtime by fixing equipment before it fails and cutting field diagnostics effort with remote operations centers—an approach well aligned with ai in industrial automation architectures that balance edge and cloud. ABB’s published guidance on predictive programs also emphasizes sector expertise, consistent sensor strategies, and process-aligned playbooks as prerequisites for sustainable outcomes, which is critical when scaling ai in automation industry initiatives across fleets and sites.

Compliance-driven environments can apply the same blueprint with additional guardrails, such as model change control, data integrity checks, and evidence generation for audits, ensuring predictive maintenance remains defensible under regulatory scrutiny while preserving value creation from ai in industrial automation.

The combination of edge inference, digital twins for scenario testing, and automated work-order creation provides an auditable chain from signal to action, which is increasingly important for regulated plants adopting ai in automation industry capabilities.

Case Study 2: Computer Vision Quality Inspection and Generative AI for Industrial Workflows

Computer vision inspection with deep learning is a leading “ai in industrial automation” use case that replaces or augments manual checks to reduce defects and lift first‑pass yield through real‑time decisions on lines. In a typical stack, cameras capture images at takt time, edge accelerators run CNNs for anomaly or defect classification, and results feed MES/SCADA to trigger reject, rework, or process adjustment, which is a common design pattern in ai in automation industry systems.

Industry narratives cite defect reductions of significant magnitude when AI inspection is paired with closed-loop feedback into process parameters, with Siemens repeatedly profiled for AI-based inspection gains as part of its digital industries strategy, reflecting maturation of computer vision within ai in industrial automation. Broader market roundups also document measurable improvements in throughput and quality when vision systems integrate into scheduling and maintenance loops, reinforcing the compounding benefits across operations for ai in automation industry users.

Generative AI is emerging as a force multiplier for “generative ai in industrial automation” via copilots that accelerate PLC code creation, troubleshooting, and SOPS authoring, which reduces engineering cycle times and democratizes expert knowledge on the shop floor.

Siemens Industrial Copilot, co-developed with hyperscalers, exemplifies this class: it allows engineers to generate and optimize PLC logic via natural language, and maintenance staff to access context-aware guidance, embodying generative ai in industrial automation that shortens development and issue-resolution cycles while preserving safety constraints through domain-specific guardrails.

Industry sources also detail anonymized factory cases where AI inspection plus AI-driven scheduling increased throughput and first-pass yield while cutting unplanned downtime, consistent with expected outcomes when computer vision and scheduling optimizers are integrated under ai in industrial automation programs.

In regulated industries, top-rated tools for compliance-driven ai automation in regulated industries emphasize validation frameworks, provenance, and documentation such as data lineage, model versioning, and audit trails, which apply directly to AI inspection and generative assistants on lines subject to GMP or similar regimes.

EFPIA and expert legal analyses outline how to validate AI used in production quality decisions and how to evidence model performance to inspectors, providing a compliance layer for generative ai in industrial automation used in pharma manufacturing. This ensures that ai in industrial automation solutions do not only perform technically but also satisfy “right first time” and data integrity expectations under evolving regulatory guidance.

Architecture Patterns That Make AI in Industrial Automation Stick

A reference pattern for ai in industrial automation uses layered compute: edge inferencing for latency and resilience, IIoT brokers for secure data movement, and cloud for centralized training, monitoring, and fleet analytics, which balances performance and cost at scale.

Digital twins enhance root-cause analysis and scenario testing by simulating process responses to parameter changes before applying them, accelerating continuous improvement loops central to ai in automation industry transformations.

MLOps practices—feature stores, versioned datasets, CI/CD for models, and drift monitoring—keep models trustworthy in production, which is required to sustain generative ai in industrial automation where code-generation and decision support must be controlled and reversible.

Finally, cybersecurity and access controls are foundational in regulated factories, with least privilege, immutable logs, and validated deployment runbooks supporting top-rated tools for compliance-driven ai automation in regulated industries without increasing attack surface or audit risk.

AI in industrial automation is a powerful tool for manufacturers seeking to enhance efficiency, scalability, and precision in their operations. By leveraging AI in industrial automation, businesses can address global challenges such as rising costs, talent shortages, and the demand for sustainable practices. Here are key scenarios where AI in industrial automation delivers transformative value:

- High-Volume Production: AI in industrial automation excels in optimizing large-scale manufacturing. Smart factory automation, powered by AI in industrial automation, streamlines production lines by analyzing real-time data to adjust workflows and reduce cycle times. For example, AI can dynamically balance assembly lines, ensuring bottlenecks are minimized and throughput is maximized, keeping manufacturers competitive in high-demand markets.

- Complex Quality Control: In industries like pharmaceuticals and electronics, precision is critical. AI in industrial automation enables top-rated tools for compliance-driven AI automation in regulated industries to achieve near-perfect quality control. By using computer vision and machine learning in industrial automation, AI systems detect micro-defects in real-time, ensuring compliance with strict regulatory standards and reducing costly product recalls.

- Aging Equipment: AI in industrial automation is ideal for extending the life of legacy machinery. Predictive maintenance with AI, a cornerstone of AI in industrial automation, analyzes sensor data to forecast equipment failures before they occur. This proactive approach minimizes downtime, extends equipment lifespan, and reduces maintenance costs, making AI in industrial automation a cost-effective solution for manufacturers with older infrastructure.

- Sustainability Goals: As environmental regulations tighten, AI in industrial automation supports green initiatives. Cost-effective AI automation optimizes energy consumption by adjusting machine operations based on real-time demand, reducing waste and lowering carbon footprints. For instance, AI in industrial automation can fine-tune HVAC systems in factories, aligning with sustainability goals while cutting operational costs.

- Supply Chain Optimization: AI in industrial automation enhances supply chain efficiency by predicting demand fluctuations and optimizing inventory management. By integrating AI-driven industrial solutions, manufacturers can reduce overstock, minimize delays, and improve logistics coordination, ensuring seamless operations in dynamic markets.

- Workforce Augmentation: In regions facing talent shortages, AI in industrial automation bridges the gap by automating repetitive tasks and augmenting human capabilities. For example, collaborative robots (cobots) powered by AI in industrial automation work alongside employees, boosting productivity while maintaining flexibility in small-batch production.

Manufacturers facing cost pressures, talent shortages, or the need to modernize operations can leverage AI in automation industry to stay competitive. By adopting AI in industrial automation, businesses unlock scalable, efficient, and sustainable solutions tailored to their needs. 👉 Discover how HBLAB’s AI-driven industrial solutions can transform your operations!

HBLAB – Your Partner in AI in Industrial Automation

HBLAB is a leader in AI in industrial automation, delivering AI-driven industrial solutions for global manufacturers. With 630+ professionals, including 30% senior-level experts with over 5 years of experience, HBLAB combines technical prowess with business acumen. Our CMMI Level 3 certification ensures process excellence, while our AI expertise since 2017, including partnerships with VNU’s Institute for AI, drives innovation.

HBLAB’s flexible engagement models—offshore, onsite, or dedicated teams—offer cost-effective AI automation, saving significant costs compared to in-house solutions. From predictive maintenance to quality control, our scalable AI solutions integrate seamlessly with existing systems, ensuring compliance with GDPR and ISO 27001. Whether you’re optimizing a smart factory or retrofitting legacy equipment, HBLAB empowers your digital transformation.

Conclusion

AI in industrial automation is transforming manufacturing, delivering efficiency, cost savings, and sustainability. From predictive maintenance with AI to smart factory automation, AI empowers manufacturers to overcome global challenges like talent shortages and rising costs. With generative AI in industrial automation and HBLAB’s expertise, the future of smart factories is here.

👉 Start your AI journey with HBLAB’s scalable AI solutions!

FAQs

Q: How is AI used in industrial automation?

A: AI in industrial automation leverages machine learning, computer vision, and IoT to optimize processes, predict equipment failures, and enhance quality control, reducing downtime.

Q: How can AI be used for automation?

A: AI in automation industry automates repetitive tasks, optimizes workflows, and enables real-time decision-making, boosting productivity.

Q: What is one potential drawback of AI in job automation?

A: A key drawback of AI in industrial automation is workforce resistance due to job displacement fears, addressable through reskilling programs.

Q: How to use AI in industrial maintenance?

A: Predictive maintenance with AI analyzes sensor data to forecast failures, reducing maintenance costs.

Q: How is AI used in the auto industry?

A: AI-driven industrial solutions in automotive optimize assembly lines and quality control, improving efficiency.

Q: What is one of the main technical challenges of generative AI?

A: Generative AI in industrial automation struggles with precision in high-stakes environments, requiring robust training data.

Q: What are three examples of automation?

A: Examples include smart factory automation, robotic assembly, and predictive maintenance with AI, enhancing efficiency and safety.

Q: Can AI replace automation?

A: AI in industrial automation enhances rather than replaces automation, adding intelligence to fixed systems for adaptability.

Q: What is the role of AI in process automation?

A: AI in automation industry streamlines processes through real-time analytics and optimization, cutting cycle times.

CONTACT US FOR A FREE CONSULTATION

Read more:

– AI in Ecommerce (2025): Extraordinary Trends Redefining Online Shopping Worldwide

– Agentic AI In-Depth Report 2025: The Most Comprehensive Business Blueprint

– Agentic Reasoning AI Doctor: 5 Extraordinary Innovations Redefining Modern Medicine