Artificial intelligence is transforming supply chain management at an unprecedented pace, with the global AI in supply chain market projected to reach $192.51 billion by 2034, growing at a remarkable 39% CAGR.

As businesses face increasing complexity in global logistics, AI emerges as the critical enabler of efficiency, resilience, and sustainability across the entire supply network.

What is AI in Supply Chain Management?

AI in supply chain management refers to the application of artificial intelligence technologies—including machine learning, predictive analytics, natural language processing, and computer vision—to optimize logistics operations, enhance decision-making, and automate complex supply chain processes.

Unlike traditional supply chain systems that rely on historical data and static rules, AI-powered platforms analyze vast amounts of real-time data from multiple sources to generate intelligent insights and automated responses. This includes everything from demand forecasting and inventory optimization to route planning and supplier risk assessment.

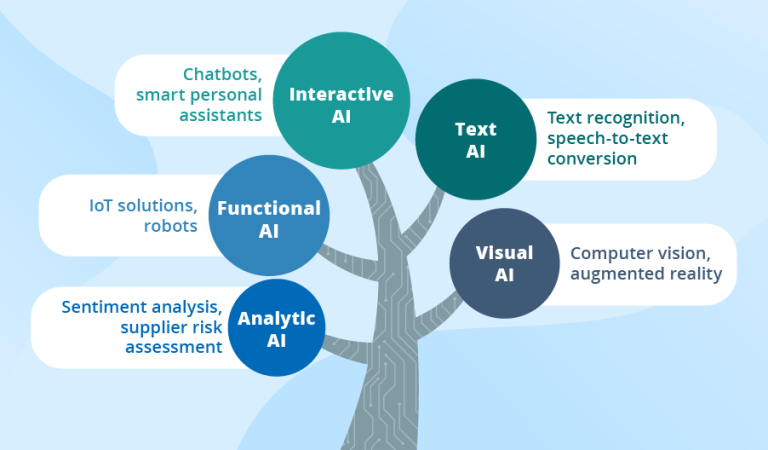

The technology encompasses various AI subsets working together:

- Machine Learning algorithms that continuously improve forecasting accuracy

- Predictive Analytics that anticipate disruptions before they occur

- Computer Vision for quality control and inventory tracking

- Natural Language Processing for contract analysis and supplier communication

- Generative AI for scenario planning and strategic decision support

How AI Works in Modern Supply Chains

AI transforms supply chain operations through three fundamental mechanisms: data integration, pattern recognition, and automated decision-making.

Data Integration and Real-Time Processing

Modern AI systems aggregate data from diverse sources including ERP systems, IoT sensors, weather forecasts, social media sentiment, and market indicators. Amazon’s AI platform processes over 2 billion data points daily from 700+ vessels in its maritime logistics operations, analyzing everything from equipment performance to fuel consumption patterns.

Intelligent Pattern Recognition

Machine learning algorithms identify subtle patterns in supply chain data that human analysts cannot detect. Coca-Cola’s AI system processes 600+ variables per product-market combination, predicting demand fluctuations with 85% accuracy up to 12 weeks in advance.

Automated Decision-Making

AI systems make autonomous decisions within predefined parameters, from automatic inventory replenishment to dynamic route optimization. This reduces response times from days to minutes while minimizing human error.

Key Benefits of AI in Supply Chain Operations

AI in supply chain operations is transforming how businesses manage logistics, inventory, and procurement, driving efficiency and resilience. By leveraging artificial intelligence in supply chain management, companies achieve significant cost savings, improved accuracy, and enhanced decision-making. Below are the key benefits, enriched with additional AI in supply chain keywords for higher density.

Enhanced Demand Forecasting Accuracy

AI in supply chain forecasting outperforms traditional methods by integrating external data like weather, economic trends, and social media sentiment. Early adopters report a 15% reduction in logistics costs and a 35% decrease in inventory levels, alongside a 65% improvement in service efficiency (Procurement Tactics). For example, Unilever’s AI-driven supply chain platform uses 26 external data sources, including social media and weather, boosting forecast accuracy from 67% to 92% at the SKU-location level. AI in supply chain forecasting enables proactive planning, reducing waste and enhancing customer satisfaction.

Optimized Inventory Management

AI in supply chain systems dynamically adjust inventory based on real-time demand, seasonal trends, and supply constraints. Walmart’s artificial intelligence in supply chain management across 4,700 stores has slashed inventory costs by $1.5 billion annually while maintaining a 99.2% in-stock rate. By leveraging AI-powered supply chain solutions, businesses minimize overstock and stockouts, ensuring cost-effective supply chain operations. AI in supply chain inventory management also enhances responsiveness, aligning stock levels with market fluctuations.

Intelligent Route Optimization

Transportation costs are a major supply chain expense, but AI in supply chain optimization reduces them significantly. UPS’s ORION system, a leader in AI-driven supply chain logistics, processes 30,000 route optimizations per minute, saving 38 million liters of fuel annually and cutting 100,000 metric tons of CO2 emissions. AI in supply chain transportation ensures efficient routing, reducing delivery times and environmental impact, making it a cornerstone of smart supply chain management.

Predictive Maintenance and Risk Mitigation

AI in supply chain predictive maintenance minimizes downtime and risks. Maersk’s AI-powered supply chain for maritime logistics reduced vessel downtime by 30%, saving $300 million annually and cutting 1.5 million tons of carbon emissions. By using AI in supply chain risk management, companies proactively address disruptions, ensuring operational continuity and sustainability. Artificial intelligence in supply chain operations enhances reliability across global networks.

Generative AI: Transforming Supply Chain Planning

Generative AI in supply chain is revolutionizing operations, shifting from reactive to proactive strategies. The market for AI in supply chain management is projected to grow from $640 million in 2024 to $27.4 billion by 2034, at a 45.6% CAGR (Procurement Tactics). Generative AI in supply chain enhances sourcing, supplier collaboration, risk mitigation, logistics coordination, procurement accuracy, and inventory optimization, driving AI-powered supply chain efficiency.

Key Applications

Enhanced Scenario Planning: GenAI models simulate various risk scenarios, including supplier disruptions, natural disasters, and geopolitical events, allowing companies to develop comprehensive contingency plans.

Automated Contract Generation: GenAI streamlines procurement processes by automatically generating contracts, RFPs, and compliance documents based on predefined templates and requirements.

Dynamic Pricing Optimization: Generative AI models examine market conditions, customer demand, and competitor pricing to produce optimal pricing strategies that maximize revenue and profit margins.

Real-world Case Studies: AI Success Stories

Amazon: Comprehensive AI integration

Amazon uses AI end to end—planning demand, placing inventory, routing deliveries, and running fulfilment centres with robotics—to move faster and spend less. The result is lower fulfilment cost per order and higher throughput during peak seasons without sacrificing accuracy.

Scale and robotics: Reports describe hundreds of thousands of collaborative robots working with people to pick, stow, and move goods, enabling safer work and faster processing during surges. These systems reduce walking time, automate repetitive tasks, and maintain accuracy at speed.

Forecasting and inventory: AI models forecast regional demand and pre‑position stock before orders arrive, improving availability and reducing split shipments and excess inventory. This shortens delivery promises and supports Prime‑level service.

Planning automation: Automated decisioning compresses planning cycles from multi‑day manual exercises to near real time, so the network adapts quickly to weather, traffic, and disruptions. That agility lowers expediting spend and stabilizes service.

Tangible outcomes: Public write‑ups cite sizable logistics savings (for example, reported savings in 2020 attributed to AI‑enabled optimisation) and significant gains in processing speed and safety from AI‑guided systems like Sequoia. In practice, this translates to faster sortation, fewer touches, and improved on‑time performance.

Why it matters: AI makes Amazon’s giant network behave like a nimble one. Stock goes where demand will be, routes shift with changing conditions, and robots keep lines moving—all adding up to lower costs and quicker deliveries.

Zara: Fast fashion, faster with AI

Zara blends AI with fast design cycles to turn trends into on‑shelf products in days, not months. The company combines RFID, predictive analytics, and AI‑guided logistics to keep stores supplied with what shoppers want right now.

RFID visibility: Item‑level tags give real‑time views of sizes and styles in each store and DC, so replenishment is precise and quick. Associates find and count items faster, improving availability for customers.

Predictive demand: AI analyses store sell‑through, local events, and seasonality to predict which styles will move, by size and location. This reduces overproduction and stockouts while keeping the assortment fresh.

“Just‑In‑telligent” flow: By fusing just‑in‑time principles with AI, Zara routes inventory through the network with minimal delays, prioritising the right products to the right stores at the right moment.

Reported results: Summaries of Zara’s programme highlight faster inventory identification, real‑time tracking across the network, and stronger risk management that prevents disruptions from cascading into poor shelf availability. In day‑to‑day terms, that means less backroom searching, fewer disappointed customers, and fewer end‑of‑season markdowns.

Why it matters: AI helps Zara know what will sell and where, so it sends only what’s needed and gets it there quickly. That keeps racks current, reduces waste, and protects margins.

DHL: Global logistics optimisation with AI

DHL applies AI to route planning, capacity management, and exception handling across a global footprint handling millions of shipments daily. The focus is on cutting delays, reducing expediting, and improving on‑time performance.

Proactive visibility: AI systems scan live network data for disruptions—weather, traffic, and bottlenecks—and recommend reroutes or mode shifts before service degrades. Teams act sooner, avoiding costly fire‑drills.

Route and load optimisation: Algorithms build efficient tours, consolidate shipments, and balance loads across facilities, saving fuel and time while stabilising pick‑up and delivery windows.

Business impact: Third‑party overviews attribute double‑digit improvements in on‑time delivery, sizable cuts in delay incidents, and measurable savings in expedited shipping. In operational terms, that is fewer misses, fewer premium moves, and happier shippers and consignees.

Why it matters: AI turns a complex, global network into a coordinated system that sees trouble early and finds quicker paths automatically, which keeps freight moving and costs in check.

How to adapt these wins in any supply chain

- Start where data is richest: Demand forecasting and replenishment usually pay back first, because better predictions immediately reduce stockouts and excess.

- Pair people with automation: Use robots and AI for repetitive tasks and exception alerts, keeping humans on judgment calls and customer issues. This boosts safety and quality.

- Close the loop quickly: Shorten the plan‑do‑check cycle. The faster forecasts update and routes adjust, the more savings compound week over week.

- Measure what customers feel: Track on‑time delivery, in‑stock rate, and lead time. These reflect both cost and service improvements from AI

Challenges and Risks of AI Implementation

Data Quality and Integration Challenges

Poor data quality costs organizations at least $12.9 million annually on average. AI systems require vast amounts of accurate data, but many supply chains struggle with data silos and inconsistent formats.

Solution Strategies:

- Implement comprehensive data governance frameworks

- Invest in data cleansing and standardization processes

- Create unified data platforms that break down silos

High Implementation Costs

Initial AI implementation requires substantial investment in technology, infrastructure, and talent development. Organizations must start with pilot projects in high-impact areas and leverage cloud-based solutions to reduce infrastructure costs.

Talent Shortage and Skills Gap

The competition for AI talent across industries creates challenges in recruitment and retention of qualified professionals who understand both AI technologies and supply chain operations.

System Integration Complexity

Legacy supply chain systems often lack the flexibility to integrate seamlessly with modern AI platforms, requiring significant technical expertise and potential system upgrades.

How AI Enhances Sustainability in Supply Chains

AI systems can reduce supply chain greenhouse gas emissions by 5-10% while simultaneously improving operational efficiency through intelligent optimization.

Environmental Impact Areas

Transportation Optimization: AI algorithms analyze traffic patterns, weather conditions, and fuel efficiency to optimize delivery routes, reducing fuel consumption and emissions. Walmart’s AI-powered delivery route planning system has achieved substantial reductions in fuel consumption and carbon emissions.

Waste Reduction: AI-powered demand forecasting eliminates environmental waste from overstocking and understocking. RELEX food retail customers typically reduce waste by 10-40% using AI-driven platforms.

Energy Optimization: AI analyzes energy consumption patterns across supply chain facilities, identifying opportunities for improvement and recommending energy-efficient solutions.

Sustainable Sourcing: AI automates environmental supplier assessment by analyzing vast amounts of data about supply chain partners including energy usage, water consumption, and carbon emissions.

The Future of AI in Supply Chain Management

AI in supply chain management is transforming logistics, empowering businesses with smarter, faster, and more resilient operations. Far from replacing human expertise, artificial intelligence in supply chain management enhances decision-making, automates routine tasks, and drives innovation. With the AI in supply chain market projected to skyrocket, emerging technologies like agentic AI in supply chain and digital twins in supply chain are set to redefine smart supply chain management. Below, we explore the future of AI in supply chain, its impact on jobs, market growth, and cutting-edge technologies, with a focus on increasing AI in supply chain keyword density.

Will AI in Supply Chain Take Over Logistics?

AI in supply chain will not replace human professionals but will significantly enhance their capabilities, creating a synergy between technology and human expertise. According to a 2024 survey, 50% of companies anticipate new job creation due to AI in supply chain adoption, emphasizing its role in augmenting rather than eliminating roles. While AI-powered supply chain solutions automate repetitive tasks like inventory tracking and route planning, human oversight remains critical for strategic decision-making, relationship management, and ethical governance in smart supply chain operations. AI in supply chain management empowers professionals to focus on high-value tasks, ensuring AI-driven supply chain resilience and efficiency.

New Roles Emerging from AI in Supply Chain Adoption

-

AI-SCM Analysts: These professionals interpret AI in supply chain insights, leveraging predictive analytics to optimize demand forecasting and risk management in AI-enhanced supply chain management.

-

Automation Coordinators: They oversee AI-powered supply chain systems, ensuring seamless integration of automated workflows like warehouse robotics and AI in supply chain logistics.

-

AI Trainers: Specialists train AI in supply chain models using historical data, improving accuracy in applications like inventory optimization and AI-driven supply chain forecasting.

-

Ethical AI Compliance Officers: These experts ensure responsible use of AI in supply chain, aligning with regulations and ethical standards to mitigate AI in supply chain risks like data privacy concerns.

-

Supply Chain Data Scientists: Professionals skilled in analyzing AI in supply chain data to uncover trends, enhance decision-making, and drive cost-effective supply chain operations.

-

AI Integration Specialists: Experts who integrate AI in supply chain with IoT, blockchain, and cloud platforms, enabling seamless smart supply chain management.

By fostering these roles, AI in supply chain creates opportunities for professionals to upskill, ensuring AI-enhanced supply chain operations remain human-led and strategically aligned.

Market Growth Projections for AI in Supply Chain

The AI in supply chain market is poised for explosive growth, driven by the increasing adoption of AI-driven supply chain solutions across industries. Below are key projections:

-

Overall Market: The global AI in supply chain market is expected to grow from $7.15 billion in 2024 to $192.51 billion by 2034, achieving a 39% CAGR. This growth reflects the demand for AI-powered supply chain efficiency, particularly in logistics, retail, and manufacturing.

-

Generative AI Segment: The generative AI in supply chain market is projected to surge from $640 million in 2024 to $27.4 billion by 2034, with a 45.6% CAGR. Generative AI in supply chain is transforming planning, procurement, and sustainability efforts.

-

Asia-Pacific Region: Expected to grow at a 42.7% CAGR, driven by rapid digitalization, Industry 4.0 adoption, and complex AI in supply chain needs in emerging markets like India and China.

-

North America: Dominated the AI in supply chain market in 2024 with a 37.9% share, fueled by early adoption of AI in supply chain logistics and robust retail networks.

These projections highlight the transformative potential of AI in supply chain management, with businesses leveraging AI-powered supply chain solutions to reduce costs, enhance transparency, and improve resilience in smart supply chain operations.

Emerging Technologies in AI in Supply Chain

AI in supply chain is evolving with cutting-edge technologies like agentic AI in supply chain and digital twins in supply chain, driving unprecedented levels of automation and optimization. These innovations are reshaping AI-enhanced supply chain management for a more agile and efficient future.

Agentic AI in Supply Chain and Autonomous Operations

Agentic AI in supply chain introduces autonomous agents capable of making complex decisions without human intervention, creating self-orchestrating AI-driven supply chain networks. These agents optimize inventory, adjust logistics routes, and predict disruptions in real-time, enhancing AI-powered supply chain efficiency. For example, Oracle’s role-based agentic AI in supply chain automates routine tasks, allowing professionals to focus on strategic initiatives. By 2025, agentic AI in supply chain is expected to streamline end-to-end processes, making smart supply chain management more adaptive and resilient.

Digital Twins in Supply Chain and Simulation

Digital twins in supply chain create real-time virtual representations of physical supply chain processes, enabling continuous optimization and scenario testing. Amazon’s AI-powered digital twin platform for AI in supply chain simulates operations, allowing businesses to test scenarios like demand spikes or port congestion. Digital twins in supply chain integrate with AI in supply chain management to improve predictive maintenance, reduce downtime, and enhance AI-driven supply chain resilience. For instance, Maersk uses digital twins in supply chain to optimize port operations, reducing planning time from days to hours.

HBLAB: Your Trusted Partner in AI-Driven Supply Chain Solutions

In an era where artificial intelligence is reshaping supply chain management, HBLAB stands as a trusted partner for organizations seeking to harness the transformative power of AI in their logistics operations. With proven expertise in AI development and supply chain optimization, HBLAB enables businesses to build intelligent, resilient, and sustainable supply networks.

Why Choose HBLAB for AI Supply Chain Solutions

Deep AI Expertise Since 2017

HBLAB has been developing AI solutions for over eight years, with specialized experience in supply chain applications including demand forecasting, inventory optimization, and predictive analytics. Our partnership with VNU’s Institute for AI ensures access to cutting-edge research and development capabilities.

Comprehensive Technical Capabilities

Our team of 630+ professionals brings together supply chain domain expertise with advanced AI technical skills. With 30% senior-level employees having over 5 years of experience in complex AI projects, HBLAB delivers solutions that combine theoretical knowledge with practical implementation experience.

Proven Process Excellence

HBLAB’s CMMI Level 3 certification ensures rigorous quality standards and process excellence in AI project delivery. This certification demonstrates our commitment to consistent, reliable, and scalable AI implementations that meet enterprise-grade requirements.

Cost-Effective Global Delivery

Organizations benefit from 30% lower costs compared to local rates without compromising on quality or delivery timelines. Our flexible engagement models—including offshore, onsite, and dedicated team arrangements—provide the scalability and cost efficiency essential for AI transformation initiatives.

Transform Your Supply Chain with AI

Whether you’re looking to implement predictive analytics for demand forecasting, automate inventory management, or build comprehensive AI-driven supply chain visibility, HBLAB provides the expertise and partnership needed for successful transformation.

Ready to revolutionize your supply chain with AI? 👉 Contact HBLAB today for a comprehensive consultation and discover how our AI expertise can drive efficiency, reduce costs, and enhance sustainability across your supply network.

Frequently Asked Questions

How is AI being used in supply chain?

AI is being used across multiple supply chain functions including demand forecasting, inventory optimization, route planning, warehouse automation, quality control, and supplier risk management through machine learning algorithms, predictive analytics, and computer vision.

Will AI take over the supply chain?

AI will not replace human supply chain professionals but will augment their capabilities. While AI automates routine tasks, humans remain essential for strategic decision-making and relationship management. 50% of companies expect new jobs to be created from AI adoption.

Which AI is best for supply chain management?

The best AI solution depends on specific needs. Leading platforms include SAP IBP for comprehensive planning, Blue Yonder for predictive analytics, Oracle SCM Cloud for integration, and Microsoft Dynamics 365 for optimization. Many organizations adopt hybrid approaches.

What are the problems with AI in supply chain?

Key challenges include high implementation costs, data quality issues, talent shortages, system integration complexity, and organizational resistance. Poor data quality alone costs organizations $12.9 million annually on average.

How does Zara use AI in supply chain?

Zara uses AI for demand forecasting, inventory optimization, and logistics coordination through RFID tagging, predictive analytics, and a “Just-In-telligent” supply chain system, achieving design-to-shelf turnaround times as low as one week.

How can AI enhance sustainability in supply chains?

AI enhances sustainability by optimizing transportation routes, improving demand forecasting to minimize waste, enabling predictive maintenance, and automating supplier environmental assessments. AI systems can reduce greenhouse gas emissions by 5-10%.

CONTACT US FOR A FREE CONSULTATION

Read more:

– AI in Ecommerce (2025): Extraordinary Trends Redefining Online Shopping Worldwide

– Agentic AI In-Depth Report 2025: The Most Comprehensive Business Blueprint

– Agentic Reasoning AI Doctor: 5 Extraordinary Innovations Redefining Modern Medicine