Automatic technology continues advancing at accelerating pace, fundamentally transforming industries, employment landscapes, and daily life. Understanding automatic technology fundamentals, historical development, and contemporary applications enables better decision-making regarding automation technology implementation.

What Is Automatic Technology

Automatic technology represents the application of machines, systems, and digital controls to perform tasks with minimal human intervention. This encompasses a broad spectrum of technologies ranging from simple mechanical systems to complex artificial intelligence-driven platforms that operate equipment, regulate processes, and manage workflows across industries.

The fundamental purpose of automatic technology is to enhance productivity while reducing operational errors and costs. When integrated effectively, automatic technology eliminates repetitive manual tasks, allowing human workers to focus on strategic and creative responsibilities. Modern automatic technology spans manufacturing facilities, commercial buildings, residential spaces, and transportation systems, making it an integral component of contemporary life.

Automatic technology operates through interconnected components including sensors that detect changes in the environment, controllers that interpret sensor data and make decisions, and actuators that execute physical movements or adjustments. This seamless coordination between components enables automatic technology systems to function independently with precision and consistency that human operators would struggle to match.

Historical Development of Automation

The Industrial Revolution

The origins of automatic technology trace back to the 17th and 18th centuries, when steam engines replaced watermill and windmill technology in Western Europe.

In 1785, Oliver Evans achieved a significant milestone by developing the first completely automated industrial flour mill capable of continuous production without human intervention.

The early 20th century

That is when automatic technology witnessed its rapid advancement. Henry Ford’s introduction of the assembly line in 1913 fundamentally transformed manufacturing by automating repetitive vehicle assembly tasks, drastically reducing production time and establishing the foundation for modern mass production techniques.

Between the 1920s and 1950s

Electrification revolutionized automatic technology. Factories began incorporating relay logic and electric power systems, which provided more reliable and versatile control mechanisms compared to earlier mechanical solutions. This electrification phase created enormous demand for control instruments and systems that could manage increasingly complex industrial processes.

The mid-20th century

Automatic technology saw transformative changes with the invention of programmable controllers and electronic computer systems.

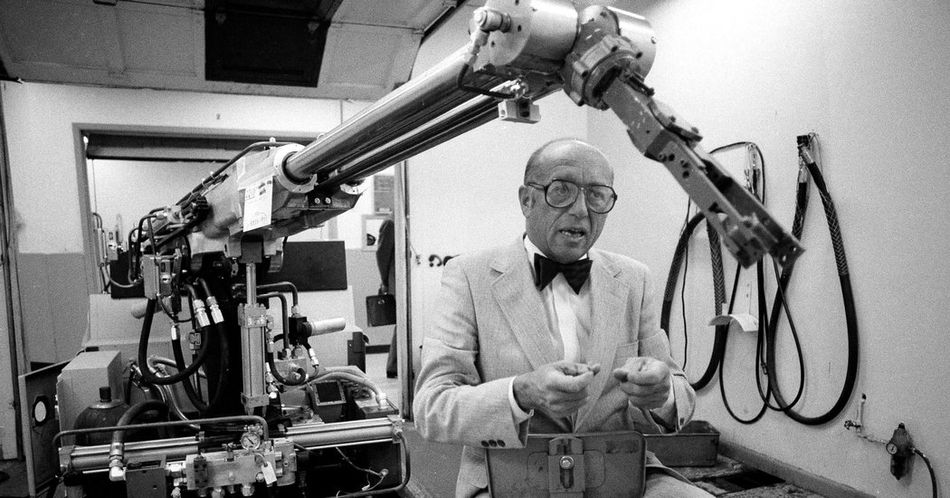

- The 1950s saw the birth of industrial robots

- The 1960s introduced programmable logic controllers that replaced cumbersome relay systems with flexible, user-friendly control mechanisms.

In 1969, Victor Scheinman invented the Stanford arm, a six-axis articulated all-electric robot that demonstrated the potential for machines to perform complex tasks like welding and assembly.

The late 20th and early 21st centuries

Automatic technology innovation was accelerating through digital computing, artificial intelligence, machine learning, and the Internet of Things. Modern automatic technology systems now possess cognitive capabilities, enabling machines to learn from experience, adapt to changing conditions, and make autonomous decisions.

How to Program Automatic Technology Remote Controls

Programming garage door remote controls represents one of the most practical applications of automatic technology for homeowners. The process is straightforward and can typically be completed in under five minutes without professional assistance.

Step One: Locate the Learn Button

Begin by accessing your garage door opener unit, which is usually mounted on the ceiling. The learn button, typically located on the back or side of the opener unit, may require removing a protective cover to reach.

Different manufacturer models use different colored buttons—some feature purple, red, or other identifying colors—so consulting your specific opener’s manual is advisable for exact placement.

Step Two: Activate Programming Mode

Press and release the learn button on your garage door opener. This action puts the system into programming mode, usually indicated by a light illuminating or a beeping sound. You now have approximately 30 seconds to complete the next step.

Step Three: Program Your Remote

Within the 30-second window, press and hold the button on your remote that you want to use for opening the garage door. Continue holding until you observe the garage door opener light blink or hear a clicking sound, which confirms successful programming.

Step Four: Test the System

Wait a few seconds, then test your newly programmed remote by pressing the designated button. The garage door should respond by opening or closing accordingly. If the door fails to respond, repeat the programming sequence.

Programming Multiple Remotes

If you need to program additional remotes, repeat the entire process for each device. Press the learn button again, then within 30 seconds, press and hold the button on your next remote until confirmation signals appear.

Important considerations include consulting your specific garage door opener’s manual, as programming methods vary slightly between manufacturers and models. Some advanced garage door openers feature wireless keypads that require entering a custom code rather than remote button programming. Always refer to your manufacturer’s documentation for model-specific instructions to ensure proper automatic technology setup.

Are Automatic Doors Digital Technology?

Automatic doors represent a sophisticated convergence of digital technology and mechanical systems, making them distinctly a form of modern digital technology.

These systems operate through coordinated interaction between digital sensors, control systems, and motorized mechanisms that function together seamlessly.

Sensor Technology in Automatic Doors

Automatic doors utilize multiple types of sensors to detect occupancy and trigger opening sequences. Infrared sensors detect heat signatures and motion, motion sensors track movement within defined zones, and pressure sensors respond to weight changes on floor mats positioned at doorway entrances.

Some advanced automatic doors incorporate proximity sensors that detect when individuals approach within a certain range, enabling touchless operation essential for hygiene-conscious environments.

Digital Control Systems

The control system represents the intelligent brain directing automatic door operations. These digital controllers interpret signals from sensors, access control devices, and safety systems to determine appropriate door behavior.

Advanced digital control systems manage opening and closing speeds, monitor timing sequences, enforce safety protocols by stopping doors when obstacles are detected, and integrate with building-wide security and automation systems.

Modern automatic doors feature highly customizable digital configurations. Operators can adjust opening and closing speeds based on traffic patterns and safety requirements, customize electrolock holding time for secure closure in high-wind environments, and tailor safety detection modes to specific building conditions.

Motor Mechanisms Controlled by Digital Systems

While motors provide the physical force for door movement, digital controllers regulate how these motors function. Permanent magnet direct current motors represent the standard choice for most automatic door applications due to their reliability and accessibility. More advanced systems utilize chain-driven spring return mechanisms or specialized servo motors controlled entirely through digital programming.

Integration with Security and Smart Technology

Contemporary automatic doors integrate with digital building management systems through access control integration, enabling selective entry via RFID cards, biometric scanners, or PIN codes. Video intercom systems allow real-time communication and monitoring, while IoT connectivity enables doors to sync with comprehensive home automation platforms and facility management systems.

The digital nature of automatic doors extends to energy efficiency features, with modern systems incorporating real-time energy monitoring capabilities that track door performance and optimize operations to reduce building energy consumption. Safety features are enforced through digital detection systems that immediately halt door movement when they identify obstacles or potential hazards.

The Four Types of Automatic Technology Systems

Automatic technology manifests in four distinct categories, each designed for specific manufacturing and operational requirements.

Fixed Automation

Fixed automation represents the most specialized and inflexible automatic technology approach, designed for high-volume production of identical products. These systems utilize specialized equipment optimized for specific repetitive tasks such as assembly, packaging, or material handling.

Industries employing fixed automation include automotive manufacturing where robotic arms perform identical welding operations, beverage bottling where assembly lines package identical products, electronics manufacturing for circuit board assembly, and consumer goods packaging. While fixed automation delivers exceptional throughput and reliability with minimal errors, it requires substantial time and investment to reconfigure for different products or processes.

Programmable Automation

Programmable automation technology enables machines to be reprogrammed for handling different tasks, products, or specifications without complete equipment redesign. This flexibility proves particularly valuable in batch production environments where product types change regularly or production volumes fluctuate.

Programmable logic controllers play a central role in this automatic technology approach, allowing quick programming changes to accommodate new product specifications. Food and beverage manufacturers frequently employ programmable automation to switch between different flavors or package sizes in response to seasonal demand.

This automatic technology type supports both customization and efficiency, though not to the extent of more flexible systems.

Flexible Automation

Flexible automation technology, sometimes called soft automation, handles variable product ranges and supports rapid product changeovers with minimal reconfiguration. This automatic technology type proves ideal for batch manufacturing environments where high product variety demands quick adaptability.

Flexible automation systems support textile manufacturing, food processing, paint manufacturing, and other industries requiring frequent product changes. The significant advantage of this automatic technology approach involves minimal downtime between product changeovers because the control system automatically conveys configuration changes without requiring physical equipment reconfiguration.

Integrated Automation

Integrated automation represents the most comprehensive automatic technology implementation, featuring fully automated manufacturing plants with minimal human involvement. This automatic technology approach enables lights-out manufacturing where robots handle every production stage from material handling through assembly and quality control.

Integrated automation technology incorporates advanced robotics, sophisticated sensor systems, artificial intelligence, and centralized control platforms that coordinate all manufacturing operations. While expensive to implement initially, integrated automation technology delivers maximum efficiency, consistency, and throughput for high-volume production facilities.

This automatic technology type supports both continuous process manufacturing and batch process manufacturing scenarios.

Essential Skills for Automation Technology Professionals

Success in automatic technology careers requires diverse competencies combining traditional engineering fundamentals with modern programming and systems integration capabilities.

As organizations increasingly adopt automation technology solutions, demand for skilled professionals continues accelerating.

Core Technical Competencies

Foundation in electrical, mechanical, or software engineering principles remains essential for automatic technology professionals. Proficiency in programming languages including Python, C++, Java, C#, and JavaScript enables engineers to develop and refine automatic technology applications.

Understanding control systems theory, industrial automation protocols, PLC programming, and industrial communication standards forms the technical backbone of automatic technology expertise.

Advanced automatic technology professionals develop competency in robotics programming, motion control systems, machine vision systems, SCADA systems, and industrial networking protocols.

These specialists understand how sensors, actuators, and controllers interact within automatic technology ecosystems, and can troubleshoot complex integration challenges.

Emerging Skill Requirements

Modern automatic technology professionals require literacy in artificial intelligence and machine learning, understanding how AI models enhance automation capabilities and enable predictive maintenance. Data science skills support process optimization and predictive analytics within automatic technology systems. Cybersecurity awareness helps protect automated systems from digital threats.

Systems thinking represents a critical competency for contemporary automatic technology engineers. Rather than viewing isolated tasks, professionals must understand how mechanical, software, and hardware components interact, and recognize potential failure points within complex automatic technology networks.

Professional Development Path

Aspiring automatic technology professionals should begin with programming fundamentals, emphasizing languages used in automation. Study control systems theory, industrial processes, sensor technology, and network protocols. Gain hands-on experience with major PLC platforms, test automation frameworks, and industrial automation software. Pursue industry certifications from automation vendors including Siemens, Rockwell, and Schneider Electric.

Building a comprehensive portfolio demonstrating progression from simple to complex automatic technology challenges strengthens career prospects. Include hardware and software automation examples, integration projects, collaborative work, and video demonstrations of functioning automatic technology systems.

Automation Technology and the Future of Employment

The relationship between automatic technology advancement and employment represents one of the most significant workforce challenges of contemporary times. Multiple research organizations project substantial employment transformation driven by automation technology innovation.

Jobs Most Vulnerable to Automation Technology

Research indicates that roles involving highly routine, repetitive tasks with minimal human judgment face the highest automation technology replacement risk. Data entry clerks, long-haul truck drivers, cashiers, and traditional accountants represent particularly vulnerable positions because these roles depend on standardized, predictable procedures that automatic technology systems execute with precision.

By 2030, McKinsey research projects that up to 30% of current U.S. jobs could be fully automated, with 60% significantly altered by automatic technology and AI tools. Administrative and clerical roles face early automation technology integration, followed by roles in finance, accounting, retail, and basic customer service.

Legal compliance tasks, content creation, transportation, and routine healthcare diagnostics increasingly succumb to automation technology advancement.

Postal service clerks, executive secretaries, payroll clerks, loan officers, and telemarketing agents face particular displacement risk from automatic technology implementation. A World Economic Forum survey revealed that 41% of companies worldwide plan workforce reductions by 2030 due to automatic technology adoption.

Jobs Least Vulnerable to Automation Technology

Certain occupational categories demonstrate substantial resistance to automatic technology displacement. Healthcare professions requiring human interaction, emotional intelligence, intuitive decision-making, and complex judgment remain relatively protected.

Teaching represents one of the safest occupations from automation technology displacement, with only approximately 27% of educational sector tasks suitable for automation. Effective teaching requires human relationships, mentorship, and adaptive communication that current automatic technology cannot replicate.

Creative industries including writing, graphic design, art, and entertainment demonstrate moderate resilience to automation technology, with only approximately 26% of tasks suitable for automation. Jobs requiring physical manipulation in unpredictable environments, such as plumbing, electrical work, construction trades, and craft skills, present substantial challenges for automatic technology systems due to environmental variability.

Occupations involving direct human interaction, such as therapists, doctors, lawyers, teachers, bartenders, and social service workers, remain substantially protected from automation technology displacement. These roles depend on complex interpersonal skills, context-dependent judgment, and empathy that automatic technology systems cannot replicate.

Jobs requiring creative problem-solving, innovative thinking, strategic planning, and management of human resources face lower automation technology risk. Skilled trades, emergency responders, and specialized professionals remain valuable because their work demands adaptability, dexterity, and judgment exceeding current automatic technology capabilities.

Recommended Workforce Response

Organizations addressing automatic technology disruption should implement comprehensive reskilling programs, offering current employees opportunities to transition into roles demanding human interaction, creativity, and complex decision-making. Educational institutions must adapt curricula to emphasize skills automatic technology cannot replicate: critical thinking, emotional intelligence, creativity, and interpersonal communication.

Individual workers should develop skills in areas where automatic technology adds value but cannot operate independently. These include roles requiring advanced judgment, creative thinking, human interaction, and complex problem-solving. Continuous learning and adaptability represent essential professional competencies in an automatic technology-driven economy.

Negative Effects and Risks of Automatic Technology

While automatic technology delivers substantial productivity and efficiency gains, implementation risks and negative consequences warrant serious consideration.

Job Displacement and Income Inequality

The most immediate consequence of automatic technology adoption involves worker displacement, particularly affecting individuals performing routine, low-skill tasks. This automation technology effect concentrates job losses among workers with lower educational attainment, potentially widening income inequality and creating economic hardship for displaced workers lacking retraining opportunities.

Unlike previous technological transitions, the pace of automatic technology advancement may exceed workforce adaptation capacity, creating temporal mismatches where workers struggle to retrain faster than automation technology eliminates their roles.

Technical Vulnerabilities and System Failures

Over-reliance on automatic technology creates dangerous dependencies where technical failures cascade through critical operations. Complex automatic technology systems require specialized expertise to maintain and repair, and unexpected technical issues can cause substantial production disruptions and costly downtime.

Cybersecurity vulnerabilities in automatic technology systems present mounting risks as interconnected industrial systems become targets for malicious actors. Data privacy concerns emerge as automatic technology systems collect vast operational data requiring protection.

Skills Atrophy and Knowledge Loss

Heavy dependence on automatic technology can result in skills degradation among technical staff. Manual troubleshooting capabilities, problem-solving intuition, and specialized knowledge about specific automatic technology systems may diminish as workers rely increasingly on automated processes.

Institutional knowledge about how automatic technology systems operate within specific business contexts can be lost as experienced workers retire or transition to other roles, making organizations less adaptable when automatic technology systems encounter unforeseen challenges.

Process and Product Inflexibility

Automatic technology systems designed around current processes lock organizations into specific configurations, reducing flexibility to adapt when market demands change or new opportunities emerge. Retrofitting or reprogramming automatic technology systems proves costly and time-consuming.

The principle “poor process, poor automation” warns that automating inefficient or poorly-designed processes amplifies those inefficiencies through automatic technology implementation. When underlying processes contain errors or inefficiencies, automatic technology systems propagate these problems at scale.

Human Interaction Degradation

Excessive automatic technology implementation in customer-facing industries can reduce human interaction quality and customer satisfaction. Automated customer service interactions, while efficient, often lack the empathy, intuition, and problem-solving flexibility that human representatives provide.

Over-automation of communication channels can alienate customers who value human connection and personalized service. This automatic technology effect particularly impacts industries where relationship-building drives customer loyalty and repeat business.

Broader Societal Risks

Potential long-term risks of automatic technology include workforce subjugation by automated systems, invasion of privacy through vast data collection networks, human error in managing complex automatic technology systems endangering civilization, and dangerous societal dependency on automatic technology for economic well-being.

The concentration of benefits from automatic technology among capital owners while costs fall disproportionately on displaced workers raises significant equity concerns requiring deliberate policy intervention.

Best Tools and Platforms for Automation Technology

The automation technology tools market offers solutions ranging from no-code platforms for non-technical users to enterprise-grade systems for complex industrial implementations.

Zapier for Workflow Integration

Zapier remains the gold standard for no-code workflow automation technology, integrating more than 6,000 applications including Gmail, Slack, Salesforce, Shopify, and ChatGPT. Zapier excels at streamlining repetitive business processes without requiring programming knowledge.

This automation technology platform enables users to create automated workflows in minutes using a visual builder interface. Zapier’s strength lies in connecting disparate business applications, automatically routing data between systems, and eliminating manual data entry tasks. The platform supports complex conditional logic and integration with artificial intelligence tools.

UiPath and Automation Anywhere for Enterprise RPA

UiPath and Automation Anywhere lead the robotic process automation segment, serving enterprises automating hundreds of complex processes. These automation technology platforms excel at automating legacy system interactions, data processing, and business rule enforcement without modifying underlying systems.

Both platforms provide sophisticated process automation technology capabilities including unattended automation, attended automation with human oversight, and AI-powered document understanding. Enterprise organizations prefer these automation technology solutions for scalability, security, and comprehensive process automation.

Microsoft Power Automate for Microsoft-Centric Organizations

Power Automate integrates seamlessly with Microsoft Office 365 and Dynamics 365, offering cloud flows for application integration and desktop flows for legacy system automation. This automation technology platform provides user-friendly interfaces with drag-and-drop design capabilities and AI Builder for advanced document and form processing.

Organizations already invested in Microsoft products benefit from Power Automate’s tight integration and lower cost compared to standalone automation technology platforms, though its capabilities outside the Microsoft ecosystem remain limited.

Selenium and Cypress for Test Automation Technology

Selenium remains the open-source standard for automated software testing, offering flexibility and broad platform support for web application testing. Cypress provides a more modern automation technology approach emphasizing developer experience through intuitive debugging and comprehensive documentation.

Both automation technology tools automate repetitive testing procedures, validate web applications before deployment, and catch defects earlier in development cycles. These automation technology platforms reduce testing costs and accelerate development velocity.

Dialora AI and ActiveCampaign for Customer Engagement

Dialora AI and ActiveCampaign specialize in automating customer interactions, lead nurturing, and support workflows. These automation technology platforms use conversational AI to handle routine customer inquiries, automate follow-up sequences, and qualify leads without manual intervention.

These automation technology solutions reduce customer support costs, improve response times, and deliver personalized customer experiences at scale. Marketing teams particularly benefit from these automation technology capabilities for campaign automation and lead management.

ABOUT US

HBLAB is a software development and IT outsourcing partner that helps B2B teams plan and ship automatic technology solutions, from automation workflows to smart product features. With a growing team of 630 plus engineers and project managers, HBLAB supports delivery across industries such as retail and ecommerce, education, and healthcare.

-

630 plus professionals to scale delivery quickly

-

Flexible engagement models such as offshore, onsite, and dedicated teams

-

AI capability and partnerships such as VNU’s Institute for AI

-

CMMI Level 3 process discipline for predictable delivery

-

Cost efficiency, often positioned as up to 30 percent lower than local rates

CONTACT US FOR A FREE CONSULTATION

Conclusion

While automatic technology delivers substantial productivity benefits, conscientious attention to workforce impacts, system vulnerabilities, and human-centered considerations remains essential. Success with automatic technology requires balanced approaches that harness automation capabilities while preserving human skills, adaptability, and meaningful employment opportunities.

Organizations and individuals who skillfully navigate automatic technology advancement will thrive, while those resisting change risk obsolescence in an increasingly automated world.

Read More:

– AI in Industrial Automation: The Definitive Guide Powering Smart Factories in 2026

– n8n vs. Zapier: From No-Code to AI-Native, truly secure and scalable Automation

– AI in Ecommerce (2026): Extraordinary Trends Redefining Online Shopping Worldwide